|

|

|

|

Shin'yō Type 1 test run

|

|

|

Shin'yō Production

by Shigeru Makino, former Navy Technical Captain

Shigeru Makino was Team Leader of the team

responsible for design and production of the shin'yō explosive motorboat.

1. Origin of Maru Yon (Shin'yō)

At the end of March 1944, the Chief of the Naval General Staff issued two

secret military resolutions to the Minister of the Navy. The first resolution

strongly requested the realization of production of nine types of special

(suicide) attack weapons. If these could be accomplished, Japan certainly would

be able to win. These nine weapon types were the following:

Maru Ichi (①) Kanamono - midget submarine to attack conventional submarine

Maru Ni (②) Kanamono - weapon to attack antiaircraft installation

Maru San (③)

Kanamono - kairyū midget submarine

Maru Yon (④) Kanamono - shin'yō

explosive motorboat

Maru Go (⑤) Kanamono - self-propelled depth charge

Maru Roku

(⑥) Kanamono - kaiten human torpedo

Maru Nana (⑦) Kanamono - radio wave weapon

Maru Hachi (⑧) Kanamono - radio wave jammer

Maru Kyū (⑨) Kanamono - shinkai

midget submarine

The nine weapon types were given code names to keep the information secret.

For example, the literal translation of Maru Yon (④) Kanamono is Circle 4 Metal

Fitting, which gives no indication of its true purpose. The other resolution

issued to the Minister of the Navy had 26 or 27 ideas that would be extremely

advantageous to the war situation if they were possible, but many of these were

farfetched notions similar to dreams.

The first resolution was studied carefully and seriously by each department

of the Navy Technical Department, but the only ideas accepted as possible to

realize were items 4, 6, and 9. At the start there were given temporary names of

Maru Yon (④) Boat, Maru Roku (⑥) Kanamono, and Maru Kyū (⑨) Kanamono, and we

started trial manufacture for them. Maru Roku was the later kaiten. As

for Maru Kyū, there was a trial manufacture and was named shinkai, but it did

not reach practical use. The Maru Yon Boat was named shin'yō.

2. Basic Construction of Maru Yon

The Naval General Staff's original concept for the Maru Yon Boat was a vessel

that would carry out a special attack with the objective of sinking a landing

craft. The boat would be an extremely light collapsible type with an outboard

motor attached that would carry out the attack with a small amount of

explosives. However, the production number goal had to be achieved.

When this concept was investigated, the request for something lightweight and

small was reasonable, but there was a large inconsistency between the results of

the loaded explosives and the goal of sinking immediately a ship of several

thousand tons. Also, in addition to the power of domestically-produced engines

being small, the possibility to achieve such production volume was nil.

Because of the goals requested by the Naval General Staff, we thought that

about 300 kilograms of explosives would be needed along with a speed of above 20

knots, and if possible about 30 knots would be desirable. On the other hand, as

for an engine that actually could be produced, we thought that there was nothing

other than an automobile engine, and we estimated that between 70 and 80

horsepower could be achieved if its generating power were increased. We

considered production of the hull and arrived at the conclusion that wooden

construction was most appropriate since the materials and production workers for

this would not compete with other production items. If we went with this

proposal, on the whole a boat of about one ton with a speed of 25 knots was

possible, but the handling of this extremely light boat had a long way to go.

Based on this concept, overall agreement with the Naval General Staff was

obtained as a result of discussions, and trial production started immediately.

3. Design Concept for Maru Yon Boat

As for a domestically-produced automobile engine capable of use as the main

propulsion for a small highspeed boat of one ton, there was only the gasoline

engine produced by Nissan and Toyota for a four-ton truck. Since this engine was

heavy, it was apparent that this would be unfavorable. If this disadvantage were

not compensated for by a lightweight design for the hull, then the boat would

not be realized. In other words, as for the lightweight design, we were

determined that we must proceed based in the belief in the basic design concept

for the Maru Yon Boat. We also strongly demanded that an engine be installed on

the boat. Also, as for demonstration of speed, we could not give up on efforts

to do whatever it took regarding the important point of responsibility to

achieve it. On the other hand, we thought that we would need to remove

everything else in the boat. Because of this, Section 4 (Shipbuilding Section)

leaders felt deeply the necessity of having the Yon Maru Boat designated as a

special attack weapon, and this was able to be realized by going through various

procedures. Based on this, the Yon Maru Boat did not fall under jurisdiction of

general warships, and the aims of the production designers had the possibility

of being realized completely as each department provided cooperation with their

requests. This was a very necessary and reasonable step to realize quickly

performance improvements for the Maru Yon Boat. Through this step it was quickly

possible to have tests for increased power generation for the engine, and also a

drastic reduction of propeller shaft diameter was realized with the goal of

minimizing drag caused by additions. With regards to realization of weight and

speed, this arrangement resulted in much advantageous guidance.

It was not that we could always play our trump card. Afterward, our request

for cooperation from Section 5 (Engine Production Section) was gladly accepted,

and they shared in the work according to their regular jurisdiction. Our

gratitude cannot be expressed enough for their extraordinary efforts made on our

behalf for the boat's realization.

4. Basic Testing

One test was to increase the engine's power generation as previously

mentioned. Section 4 personnel themselves went to the Nissan and Toyota

factories and emphasized the test's necessity to those men directly involved and

requested cooperation. The result was that tests were completed in an extremely

short period. It was concluded that it would be possible to realize about 80

horsepower with the Nissan engine and about 70 horsepower with the Toyota

engine. It cannot be forgotten that Dr. Kazuo Sumibe, Tōkyō University Professor

who was resident as a consultant at the Toyota factory in a suburb of Okazaki

City, gave various relevant suggestions and also achieved success by

recommending them to company leaders.

Another test was concerning the effectiveness of the explosives. In an

experiment with a conventional underwater explosion, there was nothing that took

place on the surface. There was an opinion that in a surface explosion the

pressure produced by the explosion would disperse into the air and would not be

able to cause great damage under the surface. Without delay a test was carried

out at Yokosuka Armory with a box model of a large merchant ship at a reduced

scale of 1/3. This result was a small opening created on the surface and a large

opening produced below the surface. In other words, it was proved that even with

a surface explosion, then the large pressure from the explosion if near the

surface would be transmitted from the surface to under the surface. It was

clarified that the blast opening on the plating below the surface for a large

merchant ship caused by the Maru Yon Boat explosives would be between three and

five meters, and it led to the belief that the boat's power would be sufficient.

With completion of these tests in the middle of April, we looked for

opportunities on ways that progress could be made quickly. Needless to say,

these tests brought about a tremendous effect to heighten motivation of men

involved in the program.

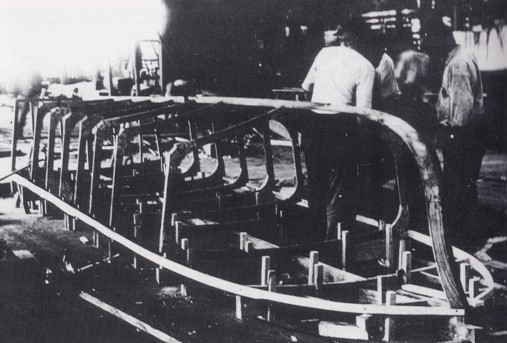

Frame production

5. Basic Design and Trial Production

In April we quickly started on the design, and we set a schedule to carry out

a test run on the auspicious date of May 27, Navy Commemoration Day. We promptly

completed the basic design, and the detailed design was prepared at Yokosuka

Arsenal. We immediately started on production.

For trial production, five wooden boat hulls were ordered from the Nihon

Shipbuilding Tsurumi Factory, and Yokosuka Armory took responsibility for

outfitting the boats. The wooden boats were based on the boat design for a Type

5 Hydroplane Torpedo Boat, but in order to reduce weight the bow was cut and

shortened, which resulted in the sacrifice of lower cruising speed. That is to

say, it was reduced to a total length of five meters from a normal length of

about seven meters. Based on this, the center of gravity when loaded with

explosives was appropriate, the hydroplaning capability was favorable, and the

realization of speed was optimal. The hull, deck, and traverse bulkhead used

waterproof plywood for everything. The framework used Chinese red ash wood, and

a small amount of zelkova (Japanese elm) wood was used for the primary longeron.

It was decided that the assembly would be with urea resin in its entirety, but

there was joint use of rivets where there was compression bonding at adhesive

joints.

There was not sufficient confidence regarding the plywood, so a

countermeasure was put in place for the worst case scenario. It was decided that

there would be a trial production of a boat with very thin steel plate and with

a stepped hull having a length of seven feet. The outside plating on the boat's

bottom was normal plating, but corrugated plating was used for the sides and the

deck with thicknesses of 0.8 cm and 0.5 cm, respectively. The hulls for the two

metal boats were made by the fittings factory of the Yokosuka Armory

Shipbuilding Section, and the factory completed the boat outfitting in parallel

with the main production.

The Yon Maru Boat trial production progressed extremely smoothly, and a trial

run was carried out according to schedule on May 27. While the steel boat did

not achieve the desired speed in the beginning, the wooden boat, which was what

was really desired, was confirmed to display capabilities according to plan, and

we decided to mass produce it.

Durability tests and wave endurance tests were carried out promptly by

Yokosuka Armory with the trial production boats. Accidents occurred twice where

both sides of the bow's exterior plating experienced fatigue and broke apart and

then the boats sank. Furthermore, based on drop tests that also were carried

out, it was decided to improve wave endurance capability by shrinking the frame

weld spacing only on the bow, strengthening the outer plating with a two-ply

application, and using a clipper model for the bow tip. Based on these changes,

the boat's overall length was increased to 5.1 meters.

The Yon Maru Boat was essentially a special attack boat, but from the

beginning design there was a mechanism to fix the rudder wheel that was

installed, and a pilot wearing a life jacket could escape out the boat's stern.

Afterward, the Torpedo School training unit carried out this escape, and it was

confirmed to be simple and safe.

6. Hull Construction

The biggest problem regarding the hull was the quality of the beech plywood,

which was the main material. If beech tree raw timber is cut down and left as

is, a rot called fuke will develop. Since plywood that used layers taken

from such raw timber had a considerable percentage that escaped inspection and

were contaminated, it was brought to the attention of production workers that

they should not use such boards.

Next there was technical guidance regarding the framing of the wooden

framework. For close adhesion work, urea resin exhibited an extremely high level

of adhesion strength, but when applied with a certain thickness, a phenomenon of

rapid aging occurred, and the adhesion strength was lost. Therefore, it was a

priority that everyone in the adhesive department perform their work without

leaving any space, but to maintain this during production was exceedingly

difficult. Since the majority of Maru Yon Boat production factories were

handling lightweight wooden highspeed boats for the first time, groups were

formed that made a tour of factories around the country. First, they were made

aware of the importance of this boat, and they were provided guidance to fulfill

manufacturing technical requirements. Also, measures were taken to point out

defects in actual boats.

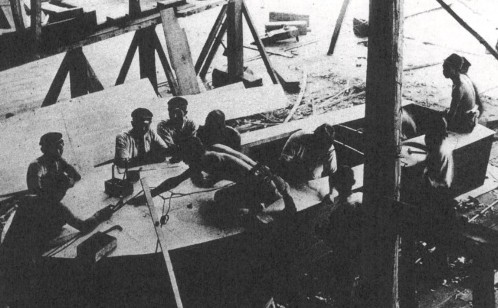

Boat framework (keel)

7. Cooperation on Training

Tactical training was carried out at the Torpedo School, and the initial

manufactured boats were assigned entirely for training use. Later a torpedo

training facility was established at Kawatana on Ōmura Bay as a Torpedo School

branch school, which was designated solely for training of Maru Yon Boat pilots.

Boat pilots came primarily from the Yokaren (Naval Preparatory Flight Training

Program).

We frequently competed even in training, and we worked out steps to address

problems of boat performance improvement. These steps were thought out based on

training. In tests carried out near the breakwater of Yokosuka Naval Port, there

was research on (1) how to clear different types of navigational barriers if the

boats attempted to enter a harbor and (2) the relationship between the

detonation device structure and the angle limits when setting off a detonation

in a diagonal ramming during a taiatari (body-crashing) attack. Also, it was a

quite late period when a test was carried out where a specially-made balloon was

produced as a training target to be towed by a torpedo boat. Besides these,

there was an experiment to load the boat with a larger fuel tank to extend its

cruising range and experiments to equip the boat with a machine gun and a rocket

launcher, and these were later implemented.

There was a large-scale general staged maneuver carried out at Sasebo

Arsenal. The boats were carried by transport trucks from air-raid shelters on

land to the place on shore where they would be launched. Several dozen boats

maneuvered to the place where they would attack enemy ships. It was an amazing

event.

Those men who had been involved with training were invited to a farewell

party for the Chichijima Special Attack Squadron, which was the first

operational unit. The Torpedo School's somber party was held the night before

departure at Komatsu Restaurant in Yokosuka, and the following morning there was

a huge sendoff when the squadron departed from Yokosuka Harbor. An SB craft

(second-class transport ship) was responsible to carry the boats and men to the

island of Chichijima.

8. Engine Problems

When rigorous training began with boats produced for actual use, engine

problems appeared one after another. Causes of the problems included no gasket

countermeasures had been implemented to take into account that cool seawater was

used directly with the engine that was originally designed for cool fresh water,

seawater vulnerability of electrical parts such as the starter motor and dynamo,

no appropriate measure for exertion of continuous power output at an extremely

high level, and inexperienced handling by pilots. Based on enthusiastic

investigations by General Staff Section 5, Yokosuka Armory, and Sasebo Armory to

address these problems, at a later stage appropriate items went into limited

operational use. The strenuous efforts of those involved with this were

extraordinary. Although we can say that from the beginning we were resolutely

thorough in producing a marine boat that would not have accidents, since it

would not be used for a long duration and since there was an urgent situation

with regards to material and production, actually we made certain decisions so

long as they were not unreasonable.

The shaft bracket was a highspeed boat single support. The installation unit

cut it and did a highspeed wave endurance test while it hung down from the

shaft. From consideration of the fact that the occurrence of even the slightest

vibration was not noticed and that a shaft accident was not seen even once, it

seemed that the Yon Maru Boat's shaft had more than enough strength for the

short time that the boat would be used.

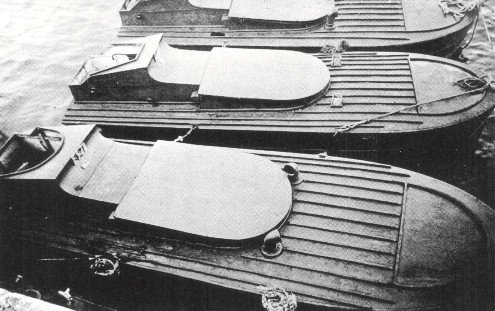

9. Production Results

With regards to Maru Yon Boat production results, 75 boats were produced in

July 1944, and afterwards in many months the production volume rose to between

500 and 700 boats. By the end of the war, 6,200 boats had been manufactured.

Just by looking at the 20% to 30% allotted to Maru Yon Boats of the Navy's

small number of truck engines at that time, it can be seen that the Navy had

high expectations for them. The Navy Technical Department responded well to

these expectations and produced actual results up to 85% of demand. These were

remarkably good results not seen with other engine types.

Excellent production results could be achieved so long as there was a

sufficient allotment of engines. Also, there was little competition from other

programs for other materials and manpower, and the boat was a simple structure

to assemble with few departments that were involved. Probably the primary reason

for these favorable results was that production went forward until the end

without any significant changes in the original design.

Shin'yō Type 1 assembly work

at Yokohama Yacht Chōshi Factory

10. Technology Level of Maru Yon

At the initial training by the implementation unit at the Torpedo School,

various deficiencies and improvement points were pointed out. However, with

regards to the basic design, it was thought that there was no room whatsoever

for these to be incorporated. It was because we believed strongly that from a

technological standpoint the best design had been produced and it was the

highest-level product technologically at that point in time. That belief was

shaken, and I heard at some point that some wanted to challenge the men in

charge, but there was no compromise in principles. Based on continued testing,

finally its real value was understood. Later this led to obtaining cooperation

for improvements in performance and production.

Looking technologically, the men involved with the Maru Yon Boat considered

it their pride as a lightweight high-performance boat.

11. Persons Responsible for Design

The Section 4 men involved in the basic design at that time were Section 4

Director Vice Admiral Iwakichi Ezaki, Planning Chief Rear Admiral Yūki Katayama,

Design Chief Rear Admiral Masatsune Yagasaki, Team Leader Captain Shigeru

Makino, and the following design personnel: Engineer Shō [1] Koyama, Technical

Lieutenant Eiichi Watanabe, Engineer Torao Ōno, Technical Lieutenant Junior

Grade Ryō Hayase, Technical Lieutenant Junior Grade Keitarō Takagi, and others.

Design skills based on Engineer Koyama's deep knowledge and proficiency

concerning highspeed boats produced excellent results without equal in the basic

plan for the Maru Yon Boat. Afterward, he established detailed technical

guidelines for manufacturing operations. His contributions to production of the

Maru Yon Boat were tremendous. I as the Personnel Leader, other than carry out

my duties to communicate the technical knowledge of my competent staff members,

did nothing more than only provide encouragement. When I look back, it is

embarrassing.

Note

1. The given name of Shō is uncertain since his

given name of Japanese (捷) has several possible readings, and the correct

reading could not be confirmed. Shō is one of the more likely readings.

Source

This article comes from pages 22 to 27 of Volume 1 of the following book:

Shin'yō Association (Shin'yōkai), ed. 1990. Ningen heiki: Shin'yō

tokubetsu kōgekitai (Human weapon: Shin'yō Special Attack Corps). Shirō

Arai, general editor. Two volumes. Tōkyō: Kokushokankōkai.

Shin'yō Type 1 Boats

Translated by Bill Gordon

July 2025

|